Suits SYSTEM

134MR

135X5 MR

1955MR

MR needle – for automated sewing processes with multidirectional function

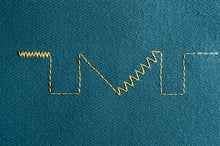

In the sewing industry, increasing use is being made of automated sewing systems which place stringent demands on the sewing needle. Particularly when changing the sewing direction, when the thread is pulled out of the needle eye in different directions, changes of the thread twist can lead to an unstable loop. Standard needles reach the limit of their capability here, which results in sewing problems such as needle breakage, untidy seams (skipped stitches, thread breakage) and material damage. The Groz-Beckert MR needle is capable of dealing with these demands and so provides increased process reliability.

Since 1980, precision needles made by Groz-Beckert have been plunging into every material and every knitted and woven fabric used in the sewing industry. With its concentrated know-how and inestimable wealth of experience in the development and production of precision components for the textile industry, Groz-Beckert also sets milestones in quality and solutions for this important textile sector.

- The special blade and scarf geometry gives the needle extreme bending resistance (deflection resistance), and consequently outstanding stability.

- The very deep and long scarf allows to position the hook or looper extremely close to the needle, providing optimum protection for the sewing thread.

- The special, asymmetrically shaped thread sliding area inside the eye of the needle ensures stable loop formation (also when changing the seam direction) and so avoids negative loop formation and thread twist.

- The special thread guiding area reduces the risk of thread unwinding.

Today, Groz-Beckert produces countless needle variants for its partners in the sewing industry. They are used for applications in industry, households and trade – all over the world.

- Allows extremely tight adjustment of the hook to the needle

- High immunity to skipped stitches

- Less thread splicing

- Less thread breakage

- Optimal protection of the sewing fabric

- High productivity thanks to reduced machine downtime

- Reduced production costs

Our groups of customers include machine builders, sales partners and end consumers in the sewing industry. These operate in a huge range of fields, such as outerwear and underwear, socks and hosiery, household textiles, technical textiles, packaging textiles and medical textiles, the production of shoes and leather articles and also individual household applications.

This list is constantly supplemented with new and innovative products in very diverse areas where textiles are used, e.g. for fastening carbon fibre layers in the production of carrying elements for the aerospace, shipbuilding and automotive industries.

Groz-Beckert will stand by the sewing industry during all these new developments – with innovative ideas and reliable precision technology.